- New vs. Used Lathe Machines: A Long-Term Investment That Pays Off

- The Advantage of a Brand-New Product

- Advanced Technology and Performance

- Warranty and Technical Support

- Ease of Spare Parts and Service

- Energy Efficiency and Eco-Friendly Technologies

- Fewer Breakdowns and Lower Maintenance Costs

- Price and Long-Term Value

1. New vs. Used Lathe Machines: A Long-Term Investment That Pays Off

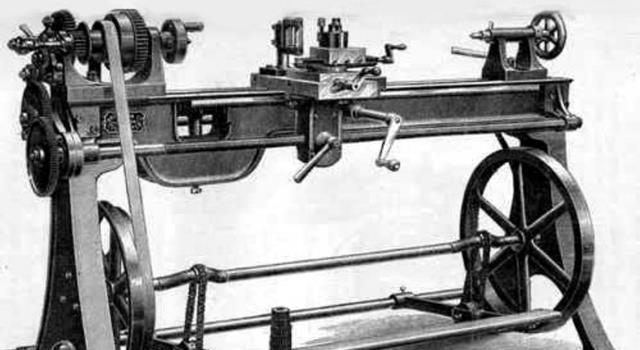

Lathe machines play a crucial role in metalworking and various manufacturing processes. However, choosing between a new or a used lathe can be a challenging decision. In this article, we’ll explore the advantages of purchasing a new lathe machine—especially in terms of technical support and spare parts availability—and why it makes more sense in the long run.

2. The Advantage of a Brand-New Product

The internal condition and machining performance of a used lathe are often unknown. Purchase decisions are typically based on the seller’s verbal assurances, which may not always be reliable. In case of an issue, it may be difficult to reach a responsible party. When buying a new lathe, you receive an official invoice and legal rights protected in writing.

3. Advanced Technology and Performance

New lathes are designed with the latest technology and enhanced performance features. These modern machines deliver greater precision, speed, and efficiency—optimizing your production process. Cutting-edge technology reduces machining time and helps achieve higher-quality results.

4. Warranty and Technical Support

When you purchase a new lathe, it typically comes with manufacturer warranty and technical support services. The warranty protects you against manufacturing defects or malfunctions, helping you avoid unexpected costs. Technical support ensures that any issues are resolved promptly and professionally.

5. Ease of Spare Parts and Service

Spare parts for new lathes are generally easier to obtain. Manufacturers keep parts in stock and ensure availability for a longer period. Additionally, accessing qualified technicians for service and maintenance is easier with new machines. In contrast, sourcing parts for used lathes can be challenging and may lead to production interruptions.

6. Energy Efficiency and Eco-Friendly Technologies

New lathe machines are equipped with energy-efficient and environmentally friendly technologies. This reduces your business’s energy costs and environmental impact. Older machines tend to consume more energy and may not comply with current environmental standards.

7. Fewer Breakdowns and Lower Maintenance Costs

New lathes are less likely to break down and typically require less maintenance. Used machines, on the other hand, may experience more frequent failures, which can lead to downtime and increased costs.

8. Price and Long-Term Value

Although the upfront cost of a new lathe may be higher than that of a used one, Foreman’s lathe pricing policy is generally suitable for end-user budgets. In the long run, a new machine can offset its cost through lower maintenance needs and superior performance. Additionally, energy efficiency contributes to lower operational expenses.

Investing in a new lathe offers many long-term advantages, such as improved performance, easier access to spare parts, and lower maintenance costs. While used machines may appear attractive due to their lower prices, the reliability and support provided by new machines make them a better choice for sustainable production.

If you’re looking for affordable, high-quality new lathes, we are here to provide the best service. Secure your investment for the future by considering a new lathe machine.

_zkmmzopp1k.jpg)