1. Machine Tools: The Cornerstones of Industrial Production

Machine tools are essential components of modern industrial manufacturing. These machines are used for cutting, shaping, drilling, and grinding various materials. Regardless of the type of machining being performed, selecting the right machine tool increases efficiency and improves the quality of the workpiece. Let’s take a closer look at the most commonly used machine tools.

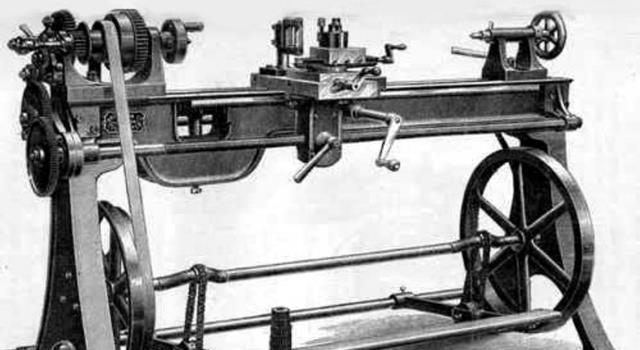

2. Lathe Machine

Lathe machines are among the fundamental tools used in the production of cylindrical parts. These machines are highly effective in processing rotating symmetrical components such as shafts or spindles. In a lathe, the workpiece rotates with the help of a chuck or spindle while the cutting tool remains stationary, removing material from the surface. Lathes are suitable for both roughing and finishing operations and can deliver high precision across a range of materials.

3. Milling Machine

Milling machines use a rotating cutting tool to process the workpiece. They are employed in machining flat surfaces, slots, gears, and various complex geometries. The flexibility of milling machines makes them versatile tools. There are two main types: vertical and horizontal milling machines. Additionally, CNC (Computer Numerical Control) milling machines are widely used for automatically and precisely machining intricate designs.

4. Drilling Machine

When it comes to drilling operations, the first machine that comes to mind is the drill press. These machines are used to create holes in materials such as metal, wood, and plastic. The drill bit rotates and penetrates the material, forming holes of the desired diameter. Adjustable speed and pressure settings allow for optimal drilling performance on different materials. Drilling machines can also be used for enlarging holes and reaming.

5. Grinding Machine

Grinding machines are used to enhance surface quality and achieve precision machining within very tight tolerances. The grinding process removes a very thin layer of material from hard surfaces. These machines are typically used for finishing operations and are ideal for jobs that require high surface quality, flatness, and parallelism. There are several types of grinders, including surface, cylindrical, and internal grinding machines.

6. Sawing Machine

Sawing machines are basic tools used for cutting workpieces. These machines use saw blades in band, circular, or disc form to cut materials. They are widely used in both metal and wood cutting applications. Sawing machines offer fast and accurate cutting, saving time in production processes. With specialized blades, they can also perform precision cuts.

Machine tools are the backbone of modern manufacturing. Each type of machine is optimized for a specific machining method and, when used correctly, can significantly improve production quality. Whether you operate in a small workshop or a large-scale factory, choosing the right machine tool is a critical step toward a successful manufacturing process.

_zkmmzopp1k.jpg)