Üretim tesislerinde makineler, kesintisiz çalışmanın temel taşıdır. Ancak her makinenin belirli bir ömrü ve sınırı vardır. Plansız arızalar, üretim kaybına, yüksek onarım maliyetlerine ve iş güvenliği risklerine yol açabilir. Tüm bu olumsuzlukların önüne geçmenin en etkili yolu, düzenli ve sistemli bir bakım takvimi oluşturmaktır.

Bu yazıda, neden makine bakım takvimi oluşturmanız gerektiğini ve etkili bir bakım planının hangi adımları içermesi gerektiğini detaylarıyla ele alıyoruz.

1. Drilling Capacity and Technical Specifications

Maximum Drilling Depth and Diameter:

Make sure the machine's capacity matches the size of the parts you’ll be working on.

Material Compatibility:

Ensure the drill press can handle materials like wood, metal, plastic, or aluminum without straining the motor or damaging the tool.

2. Precision and Repeatability

Positioning Accuracy:

Accurate table alignment and spindle control ensure your holes are clean and symmetrical.

Repeatability:

If you’re performing repetitive tasks, the drill press must deliver consistent results every time.

3. Cooling and Chip Management

Cooling System (Optional):

In high-duty use or when drilling metals, a coolant system can prevent tool overheating and extend its lifespan.

Chip Evacuation:

Effective chip removal systems are necessary to avoid blockages and ensure clean drilling, especially in metalwork.

4. Ease of Use and Control

User Interface:

Whether manual or digital, the controls should be intuitive and within easy reach.

Depth Stop and Table Adjustability:

Adjustable height and tilt of the table allow for angled or multi-level drilling operations.

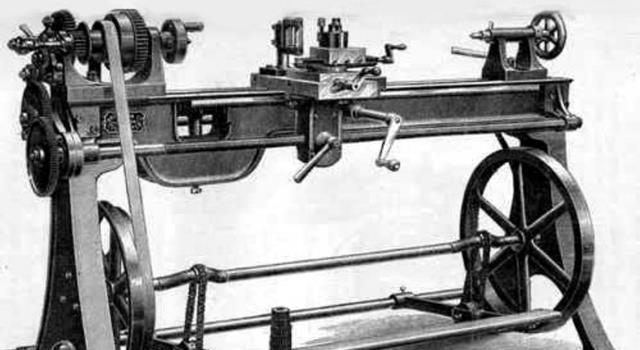

5. Structural Strength and Build Quality

Heavy-Duty Frame:

A sturdy cast iron frame reduces vibrations and increases drilling precision.

Component Quality:

The chuck, spindle, and table should all be well-built to ensure durability and reliable performance over time.

6. Brand, Service, and Spare Parts

Trusted Manufacturer:

Opt for well-known brands that offer reliable warranty terms and accessible customer support.

Service Network:

Make sure the drill press you choose has available spare parts and service centers in your region.

Choosing the right drill press requires more than just comparing prices or motor sizes. A well-matched drill press improves safety, efficiency, and long-term performance. By considering the technical criteria in this guide, you can confidently select a drill press that meets your specific needs — whether you're a hobbyist or an industry professional.

_zkmmzopp1k.jpg)