Lathes are one of the most widely used machines for shaping metal, plastic and similar materials. Numerous operations such as surface turning, drilling, stepping and surface smoothing are performed with these machines. However, using a lathe requires serious attention and technical knowledge - especially for beginners.

In this article, we cover basic safety and operating information for beginners in plain language.

1. What is a Lathe Machine?

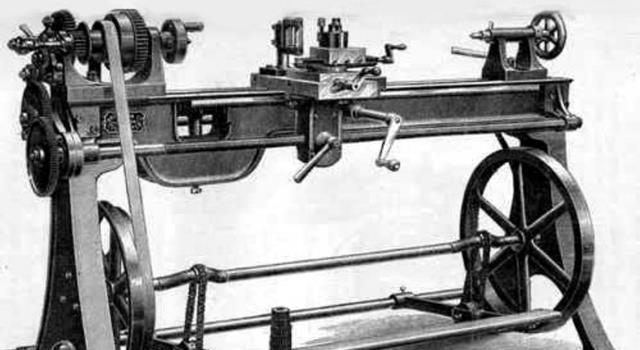

A lathe is a machine that works on the principle of shaping a rotating workpiece by removing chips with a fixed cutting tool. It is generally used in the production of cylindrical parts. It is widely preferred in workshops as well as in industrial production.

2. Things to Know Before You Start Turning

Get to Know the Machine

Familiarize yourself with the basic components such as speed knobs, centers, pen holder, carriage and spindle.

Wear Appropriate Clothing

Loose clothing, jewelry, and loose hair pose a great risk to lathe work.

Wear Eye Protection

Always wear goggles against part splashes.

Secure the Workpiece

The workpiece must be securely fastened to the chuck to prevent slippage during turning.

3. Cutting Tool Selection and Assembly

The appropriate cutting tool must be selected for each operation. The tip angle, cutting speed and tool height should be adjusted according to the material of the workpiece. The tool should be fixed exactly in the center of the workpiece and should not be left loose.

4. Speed and Progress Settings

For beginners, it is safest to start with medium speed and low feed. The lathe speed may vary depending on the type of material. For hard metals, low speed and the use of coolant is recommended.

5. Avoid Contact with Sawdust and Residual Materials

The chips generated during the process should not be picked up by hand and should not be touched even with gloves. The environment should be cleaned using a sawdust stick or brush. Contact with uncooled parts may cause burns.

6. Do not intervene before the machine stops

The part or cutting tool must never be modified while the lathe is running. The machine must be stopped and the power must be cut off before each intervention.

7. Practice with Trial Pieces

Perform your first operations by experimenting with scrap materials. Tool settings, surface quality and dimensional accuracy are better learned through this practice.

While lathe operation may seem complicated at first, following the basic rules will ensure both safe and efficient results. Each trial with patience brings you one step closer to mastery.

_zkmmzopp1k.jpg)